We developed our Z-1011 seismic snubber in 1971 following the San Fernando earthquake that hit in February. The Engineering community was shocked at the damage to the building systems and equipment despite the relatively low seismic forces. It was obvious that the static approach to seismic design was inadequate and we saw the need to develop a new snubber designed from the ground up to endure the severe dynamic cyclic loading, and limit the seismic forces imposed on the equipment to a maximum of 3G.

The all directional 3/4″ thick rubber bushing minimizes the shock to the equipment and attachments. Thick steel plate construction restrains the rubber snubber in all directions. We worked with Cal Tech to develop a computer program capable of simulating an earthquake and its effects on equipment based on the earthquakes response spectra and the mounted systems response frequencies.

The codes now require that machinery installed in critical facilities like hospitals undergo earthquake simulation testing. Since dynamic loading was always part of our thought process, it was no surprise that our Z-1011s have survived numerous shake table tests. We never sit still when we see room for improvement, and we have recently completed modifications to make these snubbers even stronger and ready to meet your needs.

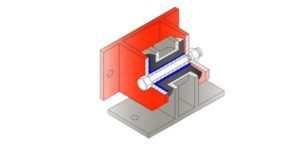

As great as the Z-1011 is, it cannot always be attached to the side of the equipment. Sometimes the equipment does not have the wall strength to accept the seismic forces, and in other cases, there is simply not enough room and we have to work from underneath.

For those situations, we have developed the SLFADA, a combination spring isolator and heavy duty snubber, but similar in concept to our Z-1011. As with the Z-1011, our SLFADA has survived the most severe shaker table tests without damage.

I was walking around the shop the other day and noticed a set of great SLFADA’s ready for shipment. The engineering shines thru.

Please take advantage of our 58 years of seismic design by letting us help solve your problems.