INTRODUCTION TO SEISMIC VIBRATION CONTROL SPECIFICATIONS FOR OFFICE BUILDINGS, COLLEGES, HOSPITAL, THEATERS AND SIMILAR STRUCTURES

To The Specifying Engineer:

Our company started calling on West Coast engineering firms as early as 1960. We opened our L.A. sales and applications office in 1965 when it became important to provide local service to the most seismically active parts of the country in California, Oregon, Washington and Alaska as well as Vancouver, Canada. Very few competitors, and especially Eastern based firms, have had this exposure. While we offered a broad line of restraints, all of these systems were in their very early stages.

In 1971 there was a major earthquake in San Fernando, California that read 6.0 on the Richter scale with horizontal ground accelerations

recorded at 0.2 g. In 12 seconds there was tremendous damage to mechanical installations with virtually every type of support failure and the engineering community became concerned.

While we did not consider ourselves expert, in 1971 the San Francisco Chapter of ASHRAE thought enough of what we had been doing to

invite Mason as the principal speaker at one of their meetings. In the three month preparation for this presentation, we intensified our studies and developed the concept of deceleration at acceptable levels and the importance of Neoprene cushioning rather than hard stops. Our philosophy was well received, and with the help of CAL-TEC in Pasadena, California, we developed a dynamic analysis program based on a response spectra as the proper approach to the problem. (See Bulletin SCS-100.)

While a few installations followed this method, we found the program far more useful in bomb blast installations in various parts of the world. Specific response spectra are not readily available for all areas, and the response spectra on a particular floor rather than at ground level, almost nonexistent. What the program did, however, was give us a better understanding of the phenomena and the need to provide materials with cushioned restraining capabilities far in excess of ground recorded or predicted acceleration levels.

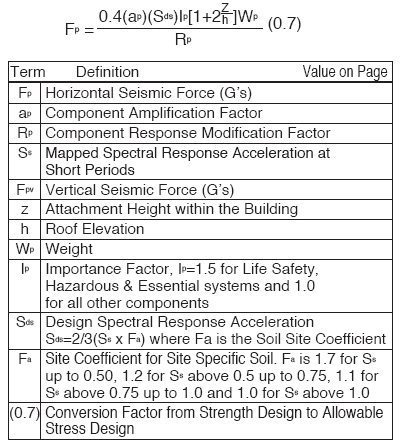

Most specifications are based on the building code in that part of the country. All of these codes work with equations for developing a maximum horizontal and vertical force. The most widely used equation for the horizontal is the following:

It is extremely important to work with these exact values when dealing with major structural components, such as the steel framing, as

a small percentage force difference might literally mean millions of dollars in savings when working to the requirements of a local code. However, vibration isolation and seismic restraints are always a minuscule percentage of a building’s cost and a small percentage of the

mechanical equipment contract as well. When we or an acoustical consultant write specifications for spring deflections, we use broad categories such as 0.75”(19mm), 1.5”(38mm), 2.5”(64mm), 3.5”(89mm), 4.5”(114mm), etc. It is not practical to specify spring deflections of 1.625(41mm), 1.83(46mm), 2.3(58mm), etc., as no manufacturer designs to these fine limits. All manufacturers supply one of their standard mountings, rather than a special design specific to those numbers to achieve the specified minimum.

Seismic restraints follow this pattern as well. To keep specifications and submittals practical rather than run calculations for each piece of equipment in every location to the exact code minimum, our suggested specification is broad band. We have selected the higher end of the calculations in a particular zone. When we are the successful vendor, the restraints we submit for your approval are generally well in excess of the specification minimums. Not only have we always preferred to work this way, but we are as concerned with your costs of errors and omissions as our own product liability. Earthquakes involve human lives. Acoustics and vibration control do not.

We cannot ask you to specify higher numbers as the contracting community tends to feel we are “loading” the requirements to increase cost. However, experience has proven that real life resonant forces exceed the static requirements.

In VCS-100, “Complete HVAC Engineering Specifications”, we explained what we considered the most important principles to follow in writing specifications to attain proper vibration isolation.

The principles in applying seismic restraints based on static codes are as follows:

1. Use the building code selected by the architect as the model for specifying horizontal and vertical maximum accelerations.

2. Simplify the specifications by specifying the higher level of forces as developed by the selected code in paragraph 1.

3. Never use isolation rails as they rotate and fail when equipment does not have adequate leg strength for direct mounting or a supplementary base is required for other reasons. Always use a one piece reinforced concrete base or a one piece structural steel frame.

4. Do not use the horizontal or vertical spring constant of an unhoused spring to calculate resistive forces. An earthquake is calculated

statically, but it is a dynamic event and springs resonate. The spring static resistance has no meaning in seismic restraint design.

5. Limit the motion of spring mounted bases using either separate double acting seismic snubbers with Neoprene cushioned interfaces, or

steel springs within self snubbing housings that are also manufactured with Neoprene cushions wherever possible. Restraining housings may be either steel, ductile iron or cast steel. Gray iron castings are not acceptable, as the lack of ductility results in shattering when subjected to shock.

6. Provide anchor bolts or drill in anchors that are seismically approved and properly selected, based on design calculations through the center of gravity. Anchor bolts must be embedded and spaced in accordance with ICC standards.

7. All housekeeping pads must be structurally doweled or bolted to the structure and adequately reinforced to resist the seismic forces on anchor bolts.

8. When steel frames or concrete piers are used to hold equipment at a higher elevation, they must be properly anchored to the structure and rigidly cross braced.

9. Install double arched rubber flexible connectors at the interfaces of equipment and piping where rubber is acceptable for the service. Use braided stainless steel hoses or stainless steel expansion joints in only those applications where the rubber expansion joints are not suitable.

10. All suspended equipment, including piping and duct work whether isolated or not, must be braced against sway and axial motion. Cable

braces are recommended for isolated equipment and either cable or solid braces for non-isolated equipment. Suspension rods may require bracing to prevent buckling when subjected to compression stress.

11. Wherever possible use OSHPD or other Government pre-approved seismic devices with pre-approved ratings. When such devices are

not available, ratings based on test are more reliable than ratings based on calculations. When testing is impractical, calculation should be made by a professional engineer with a minimum of 5 years experience in the industry. These devices are subtle and both experience and intuition are needed to make calculations meaningful.

12. Engineers and architects already carry “Errors and Omissions” insurance and this should not be a vendor requirement. All acceptable manufacturers should carry product liability with minimum limits of $2,000,000 and $5,000,000 in excess liability. Specifications and instructions together with the selection guide begin on the following page. We certainly hope that you find this tool useful and we continue to invite your comments as to its improvement.

Very truly yours,

MASON INDUSTRIES, INC.

Norman J. Mason, President