MOLDING ISOLATION BEARINGS

The following pictures will give you a better idea of the process of manufacturing isolation bearings.

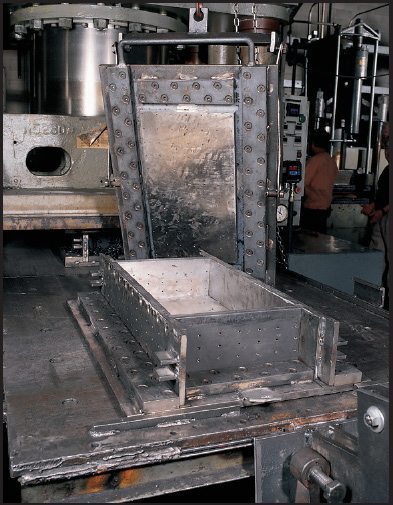

2) Completed mold for a 4” (100mm) bearing pad 18” x 24” (457 x 610mm). The mold has a base plate with 4 heavy keyed sides. The holes in the sides are for air escape and rubber flow as the uncured rubber is compressed. The closure plate is suspended temporarily. The mold is on a feed table to a huge rubber press with a 30” (762mm) cylinder and oil pressure of 3000psi (20,640 kPa). The closing force is over 2,000,000 lb. (909,090 kg.).

Norman J. Mason

President, Mason Industries, Inc.