FORM-WORK & WOODEN FLOATING FLOORS

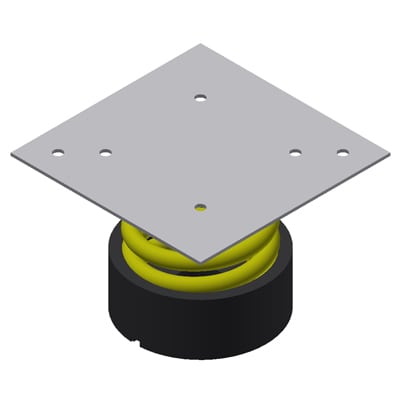

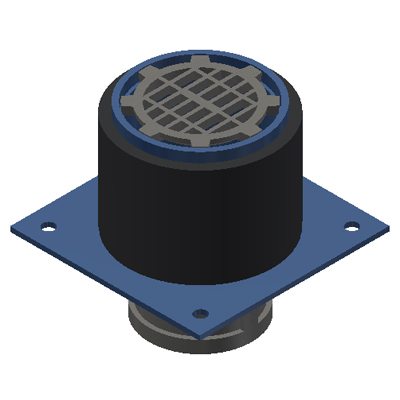

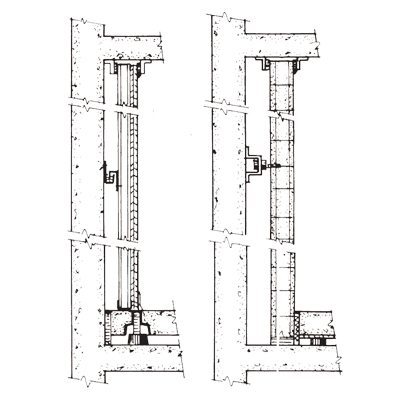

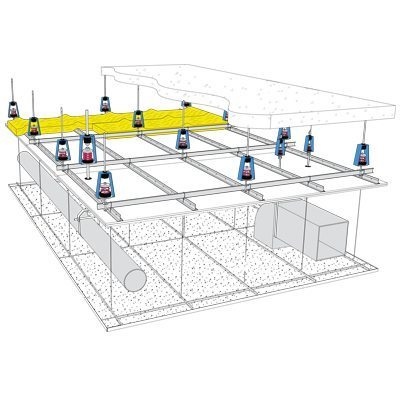

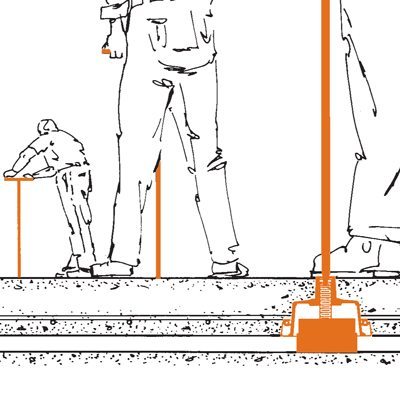

The alternate, almost obsolete, method is one whereby a continuous layer of the isolation media is used as a pouring surface. More commonly, individual isolators, the thickness of the air gap are placed in position in the field and covered with plywood or factory attached to plywood before delivery. The upper surface is covered with a plastic layer and then the reinforcing is placed on top of the plywood forms and the concrete poured at finished elevation.

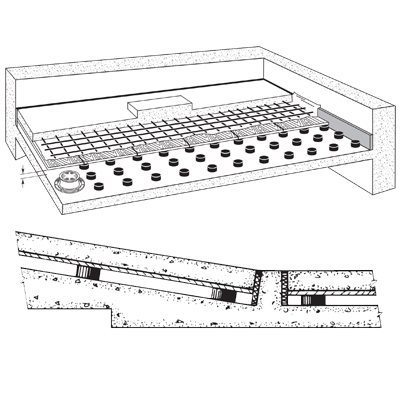

It is often necessary to provide a wooden floating floor rather than the heavier concrete construction with wood topping. Cost or weight restrictions may be the factor. In older buildings it is often necessary to improve on existing floors with a lightweight impact noise resistant construction. A resiliently supported wooden floor will reduce the rumbling noise of a bowling ball, the click, click of a woman’s heels and that portion of a typical noise generated by a piano that travels down the piano legs and into the structure. It will offer only minor reduction of airborne sound, as there is insufficient mass in the surface. In some applications on stages or in rehearsal rooms the primary purpose is relief and comfort for the dancers. Landing on concrete or hard mounted wood surfaces is very damaging to a dancer’s feet and legs.