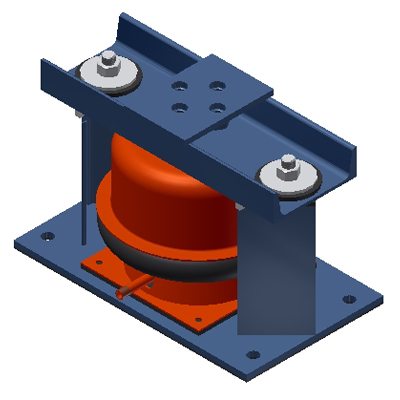

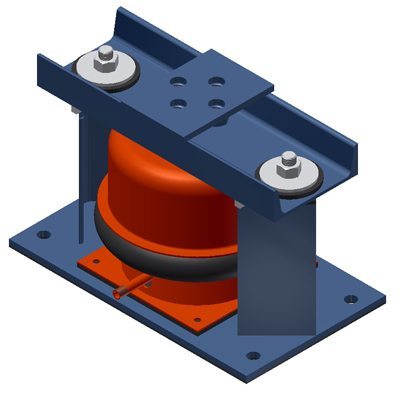

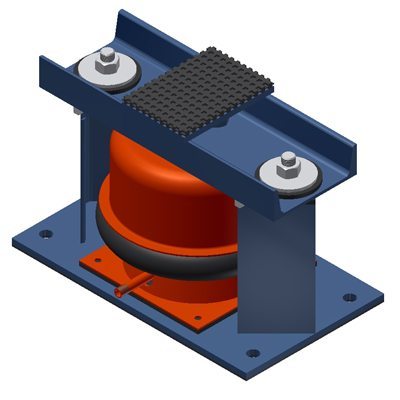

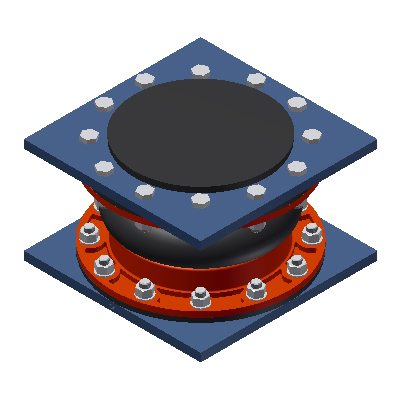

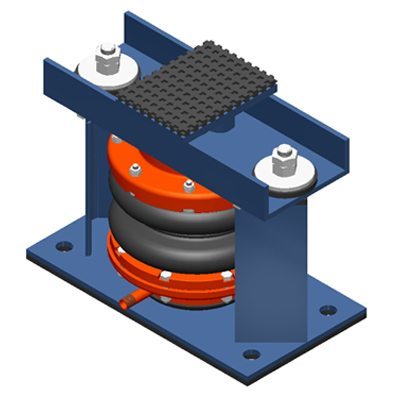

AIR SPRINGS

Air Springs shall be manufactured with upper and lower steel sections connected by a replaceable flexible nylon reinforced neoprene element. Air spring configuration shall be multiple bellows to achieve a maximum natural frequency of 3 Hz. Air Springs shall be designed for a burst pressure that is a minimum of three times the published maximum operating pressure. All air spring systems shall be connected to either the building control air or a supplementary air supply and equipped with three leveling valves to maintain leveling within plus or minus 1/8” (3mm). Submittals shall include natural frequency, load and damping tests performed by an independent lab or acoustician. Air Springs shall be type MT and leveling valves type LV as manufactured by Mason Industries, Inc.