On college campuses all over the country, the end of the school year is marked not only by graduations, celebrations, and the start of the summer vacation, but also the mad dash to get major projects and equipment upgrades completed before the start of the following school year.

At the end of May, we received a frantic call from a contractor in the midst of a cooling tower replacement at Carnegie Mellon University in Pittsburgh. They needed the cooling tower support steel frame designs, including certified wind calculations for the code prescribed 110 mph wind, and 4″ deflection restrained isolators; Right Now!

By the time we got the call there was tremendous pressure on the customer to meet the schedule, and as is typical, they were running behind and were asking for our representative, Walsh Valve, to help get them out of this jam. The cooling towers were scheduled to arrive on site in 6 weeks and without our designs and material the towers could not be set. That gave us 4 weeks, including transit time to Pittsburgh. Just to help matters, the mounts had to be hot dipped galvanized, which normally takes two weeks.

Our team of engineers and production people took the challenge. Complete steel designs, wind load calculations and fabrication drawings were completed within a week. Our production team got the mounts fabricated and ready for the galvanizer within a week and a half. And the galvanizer came through too.

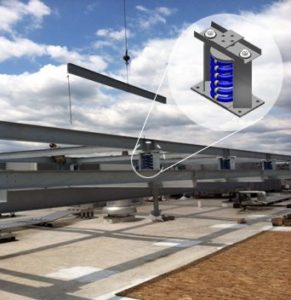

Working with several of these time sensitive projects most of the time, we are usually too busy to stop and take photos. Fortunately, the project manager was so impressed that they were kind enough to share a photo of the last piece of steel being installed only 5 weeks after we received the initial phone call and while indistinct you can see the size of the isolators too.

Please keep us in mind when you need the impossible. Mason Industries is always there for you.

Best regards,

Raj Prime

Regional Engineering Manager