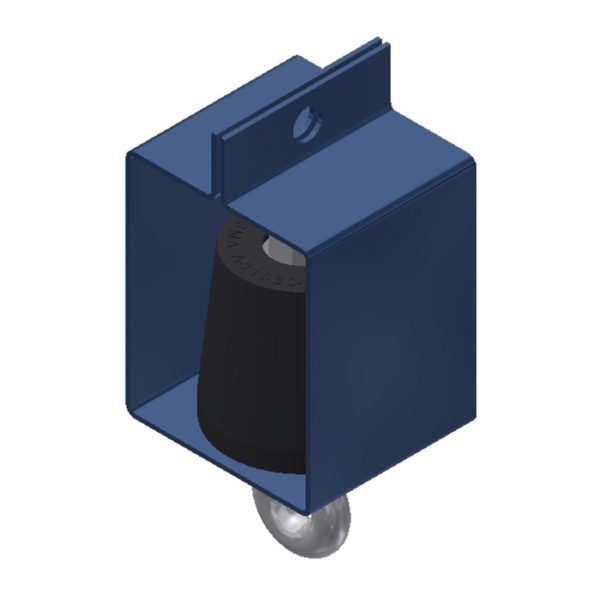

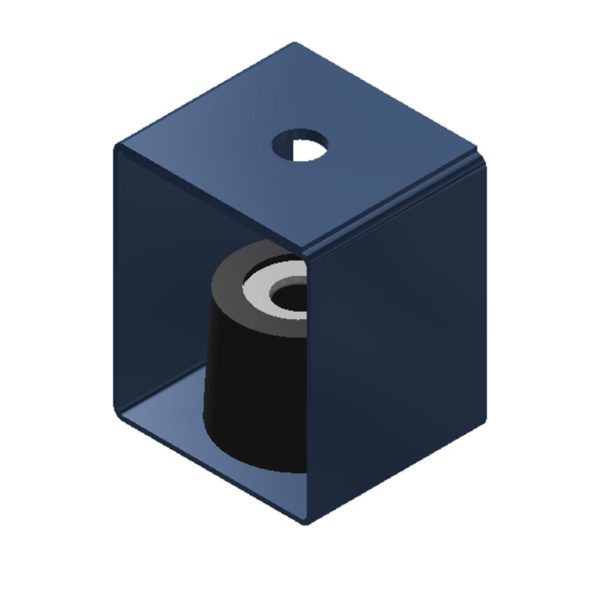

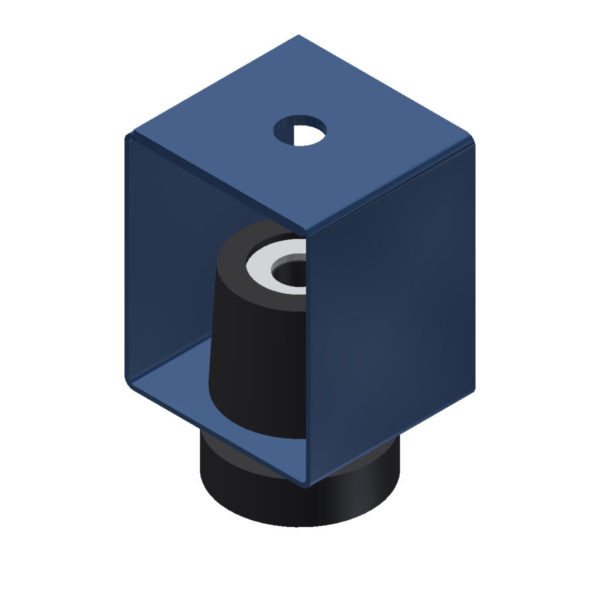

WHD – 0.20”-0.40” DEF. Range Double Def. LDS Hangers

To complete an envelope, secondary walls must be introduced with the same consideration given to mass and air gap as covered in the floor discussion. The problem is simpler, because the walls normally support only their own weight and they need not have the structural strength of the floor. Poured concrete or concrete block walls should approach the floor density. It is most important that block joints are properly filled with mortar and painting the walls so the construction is more nearly airtight helps.

The best approach is resting these walls on the perimeter of the floating floor so the floor isolation system serves the walls as well. If this is not possible, the second choice is supporting the isolated wall on the structural slab with continuous LDS pads, and providing a caulked fiberglas seal between the floating floor and the wall as described for the perimeter in the previous specifications.

| SIZE | Rated Capacity (Ibs) | Rated Defl (in) | Spring Constant (Ibs/in) | MRD (in) |

| Green | Up to 35 | 0.20 | 40 | 3/8 |

| White | 35-75 | 0.20 | 60 | |

| A-Black | Up to 45 | 0.35 | 30 | 1/2 |

| A-Green | 30-75 | 0.35 | 40 | |

| A-Red | 60-125 | 0.35 | 50 | |

| B-Red | Up to 235 | 0.40 | 50 | 3/4 |

| B-White | 180-380 | 0.40 | 60 | |

| B-Yellow | 320-650 | 0.40 | 70 | |

| BS-Blue | 500-1000 | 0.40 | 70 | 3/4 |

| CS-Blue | 1000-2100 | 0.40 | 70 | 7/8 |

| DS-Blue | 2100-4200 | 0.40 | 70 | 7/8 |