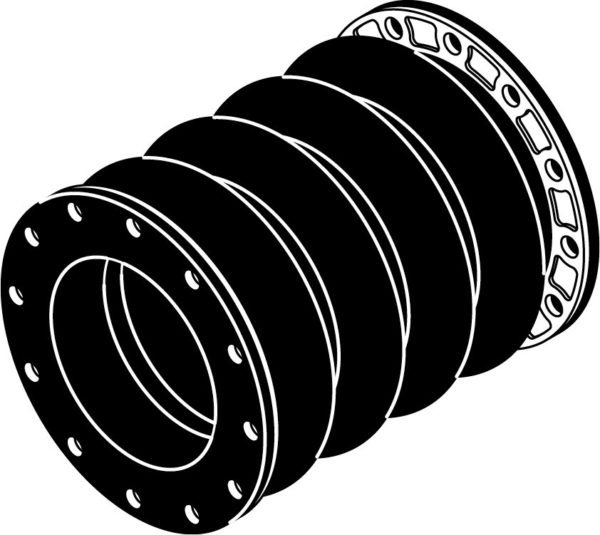

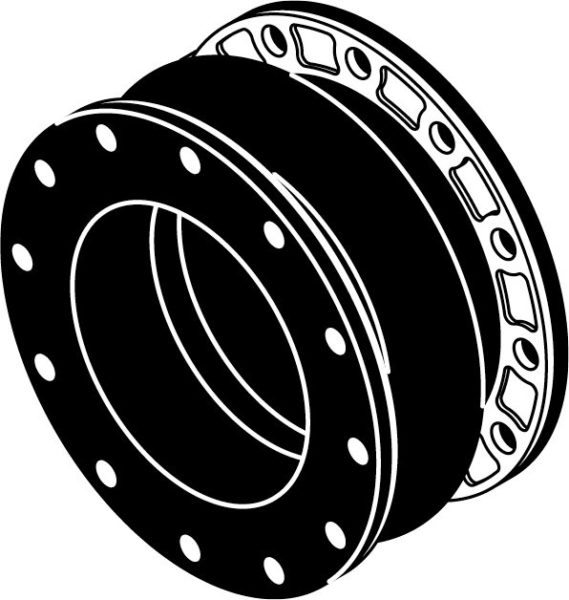

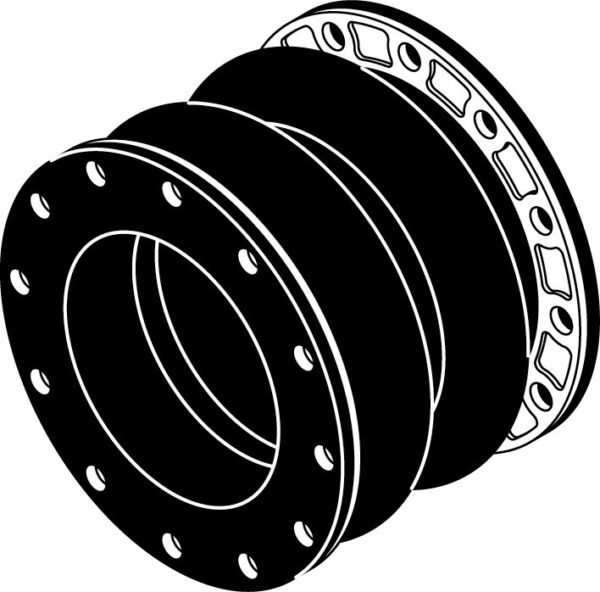

504 & HT504

Series 500

The Invincible 500 is our most rugged expansion joint. They are all hand built by our skilled craftsmen. The 1/4” minimum thickness solid elastomer tube is continuous with the flange face. Multiple plies of rubber impregnated high strength polyester or nylon tire cord form the first pressure reinforcement over the tube. Arch swell in response to pressure and arch migration are virtually eliminated by criss-crossed layers of reinforcement that pass over the arch and around steel or ductile iron rings embedded on both sides at the base of the arch. Body swell is controlled by high strength fabric or spiral steel wire. Large diameter joints are often built with steel rings in place of the wire when in addition to internal pressure, external pressure resistance is important. External pressure may come from deep burial, shallow embankment under roadways or joints inside tanks.

Uncured rubber is used to fill the voids between the spiralled wire or steel rings. A minimum of two additional plies provide protection to the carcass and the cover rubber layer is a minimum of 1/8 of an inch. All of the layered reinforcement and cover materials are carried through the full faced flanges.

Flanges are brought to thickness by heavy duty clamps that close the steel flange forms. The body is pressure wrapped by layers of nylon tape. The joint is cured in a pressurized thermostatically controlled steam chamber or in an oven for optimum performance.

After the wraps and forms are removed, the final product is a tough homogeneous expansion joint customized to safely handle the intended service. A variety of tube, cover and carcass elastomers are available and selected to provide superior chemical and aging resistance in temperatures ranging from -30° to 250°F (See Bulletin CRG-MR1).

Series HT500

The Invincible HT500 has all the construction features of the 500 combined with High Temperature capability. DuPont Kevlar® or other heat resistant fabrics replace the polyester or nylon. The tube and cover are either EPDM or Viton® for full pressure service up to 350°F and 400°F respectively.

| HT500/ HT600 |

HIGH TEMPERATURE MATERIAL Cover |

Max Oper. Temp. |

| K-E | EPDM | 350°F |

| K-V | Viton | 400°F |