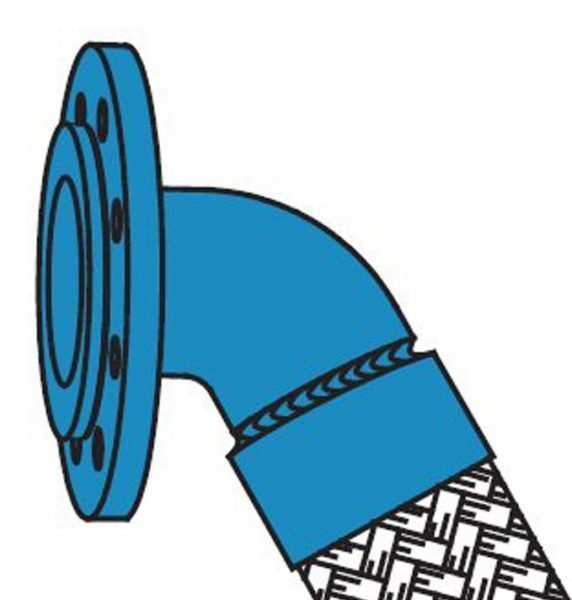

60Vee SS BRAIDED HOSE with CARBON STEEL FLOATING FLANGES

Our steam service ratings are very low in the interest of safety although our 70°F (21°C) pressure ratings are as high or higher then our competitors. All locations where failure could lead to personal injury or suffocation must be avoided. In dangerous locations we suggest housed expansion joints, solid loops, ball joints, packed devices etc. rather than thin walled flexible products regardless of manufacturer.

Consult factory with full location description as well as service conditions for higher pressure or temperature applications.

304 SS can be used up to 850°F (454°C) in applications such as engine exhaust.

When using VFL products in copper or brass water or steam systems, dielectric flanges must be used on each end to prevent leakage from galvanic action.

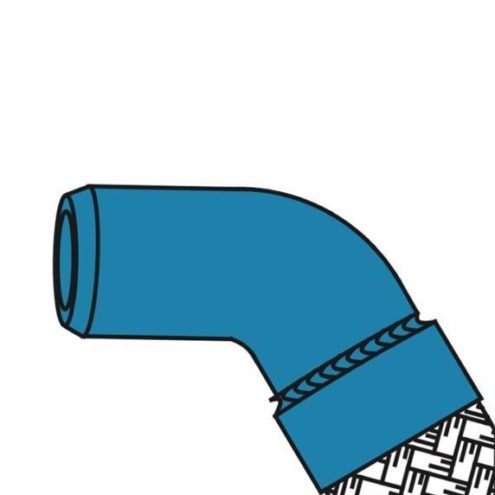

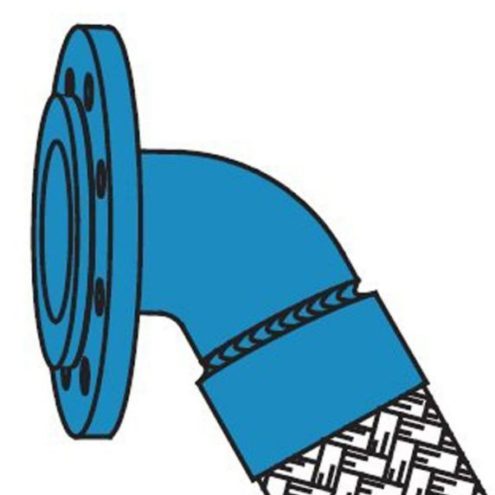

VFL

| Pipe Size & Face to Face (in) |

Live Length (in) | Corrugations per foot |

A (in) | B (in) | C (in) |

| 2 X 33 | 20 | 58 | 227/8 | 237/8 | 245/8 |

| 21/2 x 37 | 22 | 48 | 26 | 27 | 273/4 |

| 3 X 42 | 24 | 46 | 287/8 | 301/8 | 311/8 |

| 4 X 49 | 26 | 32 | 321/2 | 333/4 | 347/8 |

| 5 X 58 | 30 | 29 | 38 | 391/4 | 401/2 |

| 6 X 66 | 33 | 25 | 425/8 | 441/8 | 453/8 |

| 8 X 80 | 36 | 23 | 491/4 | 503/4 | 52 |

| 10 X 96 | 42 | 21 | 581/2 | 601/4 | 613/4 |

| 12 X 112 | 48 | 20 | 673/4 | 691/2 | 71 |

VFL-UL

| Pipe Size & Face to Face (mm) | Live Length (mm) | Corru- gations per meter |

A (mm) | B (mm) | C (mm) |

| 50 X 838 | 508 | 190 | 603 | 613 | 629 |

| 65 X 940 | 559 | 157 | 660 | 689 | 711 |

| 80 X 1067 | 610 | 151 | 733 | 762 | 781 |

| 100 X 1245 | 660 | 105 | 826 | 857 | 886 |

| 125 X 1473 | 762 | 95 | 965 | 1010 | 1026 |

| 150 X 1676 | 838 | 82 | 1083 | 1118 | 1149 |

| 200 X 2032 | 914 | 75 | 1251 | 1289 | 1324 |

| 250 X 2438 | 1067 | 69 | 1486 | 1524 | 1559 |

| 300 X 2849 | 1219 | 66 | 1721 | 1762 | 1797 |