Mountings - SLF Spring Mountings

SLF spring mountings are our standard for all high efficiency installations. This is a bare spring design with a good ratio between the diameter and the working height to assure lateral stability. Our suggested specification states “that the spring diameter shall be no less than 0.8 of the compressed height of the spring at rated load.” This is easily checked in the submittal and review process. This minimum ratio will result in a horizontal stiffness no less than 0.75 of the vertical, in virtually all cases. Should you be interested in the specifics of the design, please refer to bulletin SLF-200.

Some of our competitors are still publishing a minimum diameter chart rather than a ratio. This method of specification is questionable. If literally enforced, the call for a proprietary manufacturer’s diameter would eliminate all competition. In reality, it is only the proportion of the spring that is important and this can only be expressed as a ratio rather than a specific size. For example, if a spring were specified 5 inches in diameter and 5 inches high with a spring constant of 1,000 pounds per inch, it would have about the same lateral stability as a spring 4 inches in diameter and 4 inches high designed with better quality spring steel capable of handling higher stresses as offered by another vendor.

The minimum 50% additional travel compensates for errors that creep in because of faulty weight data. This also means the springs will operate at lower stress which further guarantees their permanency. The neoprene friction pad on the bottom acts as a sound break for some high frequencies which may travel down the spring wire. The pad also eliminates the need for bolting in virtually all applications. Bolting is preferable on steel or overhead locations.

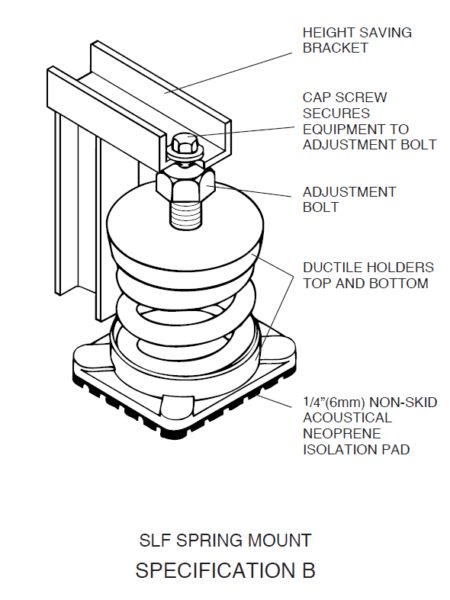

SPECIFICATION B

Spring isolators shall be free standing and laterally stable without any housing and complete with a molded neoprene cup or 1/4”(6mm) neoprene acoustical friction pad between the baseplate and the support. All mountings shall have leveling bolts that must be rigidly bolted to the equipment. Installed and operating heights shall be equal. The ratio of the spring diameter divided by the compressed spring height shall be no less than 0.8. Springs shall have a minimum additional travel to solid equal to 50% of the rated deflection. Submittals shall include spring diameters, deflection, compressed spring height and solid spring height. Mountings shall be type SLF, as manufactured by Mason Industries, Inc.