WF Steel Beam Base

Our very early specifications merely called for “sufficient base rigidity” to handle belt tension and keep the drive in alignment. There had been no criteria for base stiffness or design and every vendor had his own version of what might be minimally acceptable as there never was a unified code. Pump bases have torque and bending problems that can ruin bearings, couplings and pump seals. Before we extended pump bases to support elbows, many installations were short circuited with suction and discharge dog legs to the floor. We discussed this problem with a number of structural people as well as acoustical specialists and found that using beams with a depth equal to 1/10th of the span is a good broad working rule that can be readily checked in the submittal stage. We have manufactured thousands of these bases and find the design highly satisfactory as to appearance, rigidity and keeping base resonance high. The 14”(350mm) limit on beam depth came about because experience has shown that the 1/10th requirement is too severe on very large bases. For example, in the 1965 specification, without this limitation, we encountered situations where the distance between chiller legs was 20 feet(6000mm). Thus, the specification was calling for 24 inch(600mm) beams under a machine that already had great structural rigidity. In other situations, heating and ventilating units might be as long as 15 feet(4500mm). Thus, it would seem that 18”(450mm) beams should be used, but these were completely excessive as the whole unit might only weigh eight thousand pounds(3636 kilo). The 14”(350mm) limitation makes the specification more practical.

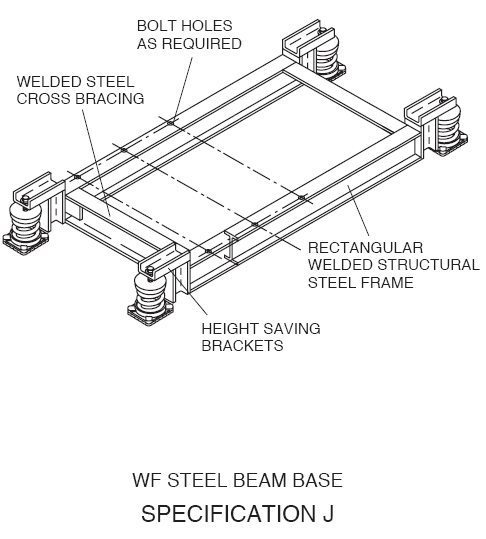

SPECIFICATION J

Vibration isolation manufacturer shall furnish integral structural steel bases. Rectangular bases are preferred for all equipment. Centrifugal refrigeration machines and pump bases may be T or L shaped. Pump bases for split case pumps shall be large enough to support suction and discharge elbows. All perimeter members shall be steel beams with a minimum depth equal to 1/10 of the longest dimension of the base. Base depth need not exceed 14”(350mm) provided that the deflection and misalignment is kept within acceptable limits as determined by the manufacturer. Height saving brackets shall be employed in all mounting locations to provide a base clearance of 1”(25mm). Bases shall be type WF as manufactured by Mason Industries, Inc.