CURB MOUNTED ALUMINUM BASES NOMINAL 1”(25mm) DEFLECTION

Not too many years ago, cooling towers and curb mounted exhaust fans were the only pieces of mechanical equipment to be found on rooftops. This has all been changed as curb mounted air conditioning equipment is commanding a larger share of the market. While rooftop equipment manufacturers do what they can to isolate components within their packages, their effectiveness is limited by shipping problems and available space as well as piping, electrical and fan connections. Unfortunately, many roofs are extremely sensitive to vibration and this makes the problem more difficult than can be handled by the manufacturer’s efforts.

Curb mounted isolation bases must:

1. Fit on top of manufacturers standard curbs and match the underside of the isolated equipment

2. Have wind and water seals that do not interfere with the spring action.

3. Resist wind forces and aging.

4. Provide as much static spring deflection as practical.

As with most of our products, all of these things had been done by custom building bases in the field to solve existing problems and this led to the design of our Curb Mounted Aluminum Base (Type CMAB). We wasted a great deal of time with various friction and shear seals and we should have known better. All of our other products never worked properly until we had a free standing spring system and curbs were no exception.

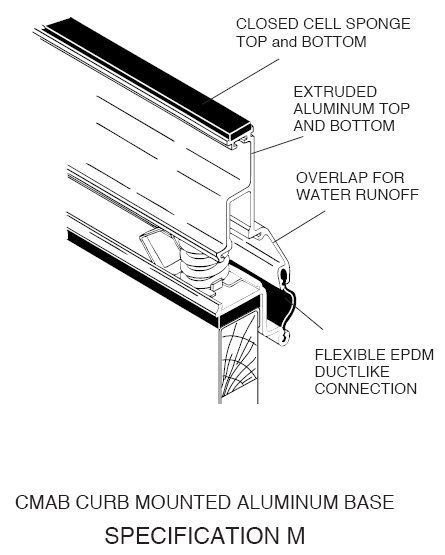

The SLF Spring Mountings are better than the type C telescoping castings because the few inches of soft sponge guiding material in the Type C often interferes with the action of the springs as happens with all telescoping designs, regardless of manufacturer. In trying to use this method for sealing roof bases, some 16 to 60 lineal feet (4800mm to 7200mm) of sponge was needed for the perimeter and the binding or freezing of the two members can completely bypass the spring isolation. Therefore, we eliminated this method and our weather seal is a truly flexible EPDM duct like seal rather than a sliding or shear fit. As a secondary precaution, the upper aluminum member overlaps the lower and acts as a water shield.

The main members of these bases are made of extruded aluminum, welded in the corners for weather-tightness. All of the steel springs are zinc electro plated or powder coated. Whenever practical, bases are shipped in one welded assembly to minimize assembly and installation time in the field. Where size does not permit one piece shipment, we minimize the number of joints and furnish simple splice kits.

Horizontal wind resistance is provided by the horizontal spring stability and supplementary rubber pads located between the two frames in the corners. There is adequate clearance between upper and lower frames and the snubbers only act during high wind.

Springs are selected from our standard A series with a rated minimum deflection of 1”(25mm) or more and 50% overtravel. Occasionally, we attain 1.25”(32mm) deflection by using more of the lightest springs in the series, but this is uneconomical except for very light equipment. The suggested specification calls for minimum 0.75”(19mm) deflection as the manufacturer’s weight and CG data may be inaccurate and we do not wish to overstate the CMAB capability. While it would be desirable to use a higher deflection series than the 1”(25mm) the design is limited by curb width and equipment contact problems. The use of taller springs having the same diameter would lead to higher deflections on paper, but the much lower horizontal stability and consequent rubbing would lower rather than improve overall performance.

CMAB curb mounted rooftop equipment bases are an excellent 1”(25mm) nominal 0.75”(19mm) deflection tool and added insurance for this type of installation on top of new buildings.

CMAB curbs should not be used in seismic zones higher than 2A.

SPECIFICATION M

Curb mounted rooftop equipment shall be mounted on vibration isolation bases that fit over the roof curb and under the isolated equipment. The extruded aluminum top member shall overlap the bottom to provide water runoff independent of the seal. Aluminum members shall house electro-galvanized or powder coated springs selected for 0.75”(19mm) minimum deflection. Travel to solid shall be 1.5”(40mm) minimum. Spring diameters shall be no less than 0.8 of the spring height at rated load. Wind resistance shall be provided by means of resilient snubbers in the corners with a minimum clearance of 1/4”(6mm) so as not to interfere with the spring action except in high winds. Manufacturer’s self adhering closed cell sponge gasketing must be used both above and below the base and a flexible EPDM duct like connection shall seal the outside perimeter. Foam or other sliding or shear seals are unacceptable in lieu of the EPDM ductlike closure. Submittals shall include spring deflections, spring diameters, compressed spring height and solid spring height as well as seal and wind resistance details. Curb mounted bases shall be Type CMAB as manufactured by Mason Industries, Inc.