FLEXIBLE METALLIC HOSES

Rubber connectors are preferable for sound and vibration attenuation, but careful consideration must be given to pressure and temperature and locations other than machine rooms. Stainless is recommended in locations away from equipment rooms and temperatures over 250°F (120°C) in continuous service or pressures beyond published rubber pressure ratings.

The very short “Pump Connectors” accepted today are based on chipping away at the 36” FF minimum used 50 years ago. These “getting the order” cost and length reductions continued, with no engineering reason, until no one dared go shorter. While simple field studies showed they were useless, we had no data to back this up, so we decided to test transverse hose stiffness. To the best of our knowledge, this had never been done before.

Bulletin BH-29 reviews these tests. We determined the force required to displace various lengths of hose 1/8” at different pressures and compared it to the transverse stiffness of the connected piping. The hose stiffness should be lower than the piping, just as spring mounting stiffness must be lower than structural stiffness in isolation work. Unfortunately, even at 36” FF we can only approach it in some sizes. We have no data on 48” lengths and it reaches a point where lengths become impractical. We did no test work on copper lines, as they are similarly too light and flexible. As we learn more, we will keep you informed. Please refer to these tests as they are the basis of our recommended specifications.

The specification calls for a minimum number of corrugations per foot to reduce stiffness. Without this requirement and fewer corrugations, hoses are cheaper to manufacture, but poorer in performance. There may be hoses even more flexible, but ours are a good criteria.

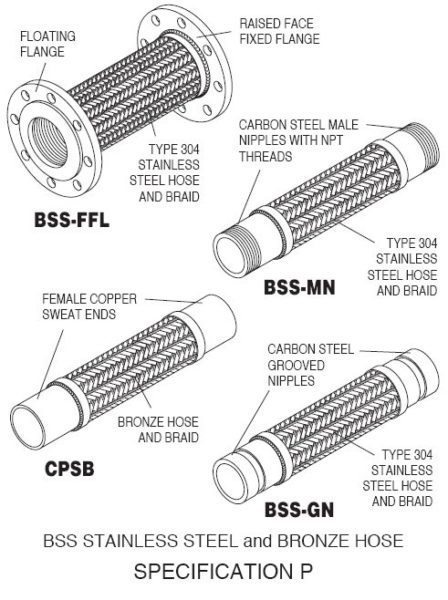

We are suggesting a floating flange at one end rather than two fixed flanges. This makes installation easier and eliminates the possibility of twisting the hose body during installation. Flanges are raised face to improve sealing pressure.

We resist welding as replacement is very costly in down time and field difficulty.

SPECIFICATION P

Flexible stainless steel hoses with a safety factor of 4 shall be manufactured using type 304 stainless steel braided hose with one fixed and one floating raised face carbon steel plate flange. Sizes 21/2” (65mm) and smaller may have threaded nipples. Copper sweat ends, 4” (100mm) and smaller, may have SS (gas service) or Bronze (water service) bodies. Grooved ends may be used in sizes 2” (50mm) through 12” (300mm). Welding is not acceptable. Minimum lengths, minimum live lengths and minimum number of convolutions per foot to assure flexibility are as tabulated. Shorter lengths are not acceptable.