PIPE ANCHORS

In the 1982 publication we used our all directional anchor for anchorage or anchoring the ends of oversized clamps that allowed piping to slide within the clamps. If the pipe was insulated, the clamps guided steel bars, welded to the pipe that protruded through the insulation. Those methods were a step forward. We continue anchoring but with welded gusseted brackets more commonly than clamps at heavy anchor points.

The use of oversized clamps and steel sliding on steel was less satisfactory as it tended to generate noise and insulating between the bars proved cumbersome. Therefore, we now use the ADA all directional anchors in anchor locations only and resilient sliding guides as described in Specification S to allow for expansion or contraction.

We have standardized on this one multi-purpose all directional anchor for simplicity of application and safety.

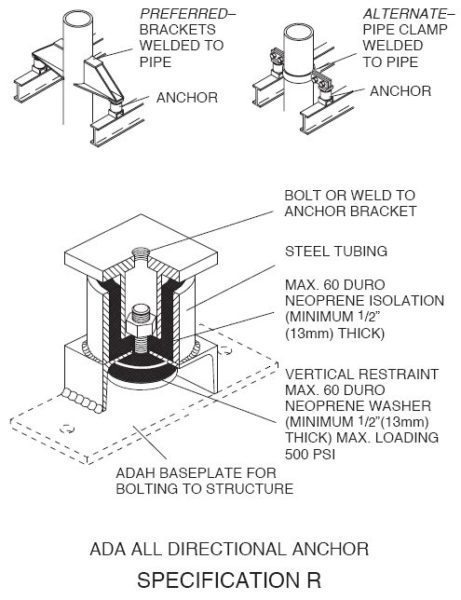

SPECIFICATION R

All-directional acoustical pipe anchors, consist of two sizes of steel tubing separated by a minimum 1/2”(13mm) thickness of 60 duro or softer neoprene. Vertical restraint shall be provided by similar material arranged to prevent up or down vertical travel. Allowable loads on the isolation material shall not exceed 500 psi(3.45 N/mm2) and the design shall be balanced for equal resistance in any direction. All-directional anchors shall be type ADA as manufactured by Mason Industries, Inc.