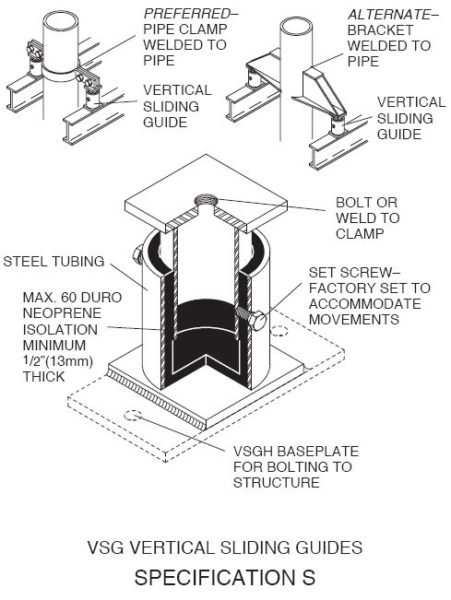

VSG Riser Guides

In 1982 we showed sliding guide locations using anchors under the ends of oversized pipe clamps around the pipe or steel guide bars welded to the pipe. This was difficult because of the need to weld the sliding bars to the pipe exterior and we found oversized clamps were not readily available. Perhaps the most discouraging part of the design was insulating between the guides and providing proper covering over the insulation. Therefore, we developed a new vertical sliding guide. This approach eliminates the sliding noise created by steel on steel within the clamp. Our literature shows the guides set for equal movements, but we can preset the guide to allow more movement upward or downward, as the case may be. If presetting does not solve the problem, the guide is manufactured with a longer body to accommodate the condition. The method is better because it utilizes standard diameter clamps and the insulation can be placed directly over the clamp with only the ends protruding to the guide. When piping is hot, the Neoprene in the guide is protected, as there is a sufficient temperature differential to the end of the clamp.

SPECIFICATION S

Pipe guides shall consist of a telescopic arrangement of two sizes of steel tubing separated by a minimum 1/2”(13mm) thickness of 60 durometer or softer neoprene. The height of the guides shall be preset with a set screw to allow vertical motion due to pipe expansion or contraction. Guides shall be capable of ±15/8”(41mm) motion, or to meet location requirements. Pipe guides shall be type VSG as manufactured by Mason Industries, Inc.