Leveling and Shock Mounts

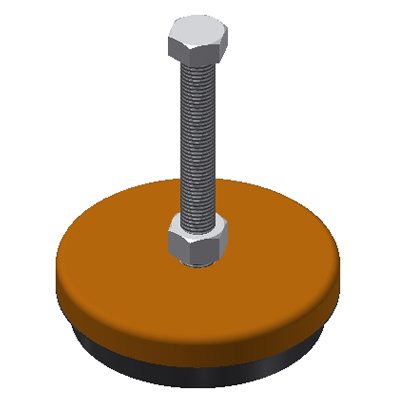

This classic style of machinery leveling mount is the most widely accepted and has been in use for over 40 years. The simplicity of up to 5/8″ 16mm leveling with a single bolt per location while providing shock and vibration isolation solves many problems. Friction is developed by the neoprene element, eliminating the need for bolting to the floor. The mounting is locked to the machine leg so it travels to a new location with the machine. When production lines must be rearranged, this reduces downtime. Typical applications are punch presses, brakes, shears, lathes, milling machines, injection molding machines, etc.

ML

| Size |

Capacity Range(lbs) |

| 3 | 100-500 |

| 5 | 500-1000 |

| 6 | 1000-4000 |

| 8 | 4000-12000 |

Neoprene Machine Leveling Mounts

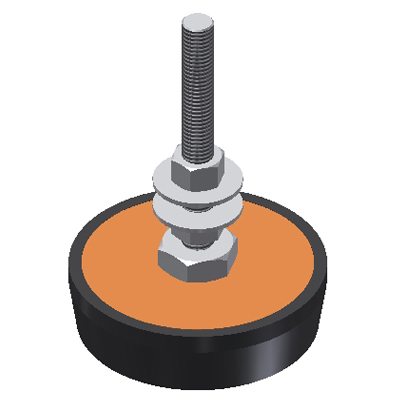

Stud type leveling mounts fill a need for a greater leveling range and are recommended for as much as 2″ 50mm of lift.

• Thick neoprene cushion

• Thick neoprene cushion

° Resists oil

° Provides friction (No bolting required)

° Isolates impact and vibration

• Long adjustment bolt will pass thru thick bases

• Zinc plated hardware

• Steel load transfer plate

• Adjustment from below is always accessible

• Cut off stud to fit in blind base holes

• Five sizes to match loads of 50 to 4000 lbs 23 to 1814 kgs per mounting

MLS

| Size | Capacity Range (lbs) |

| 250 | 50-250 |

| 500 | 250-500 |

| 1000 | 500-1000 |

| 2000 | 1000-2000 |

| 4000 | 2000-4000 |