SFFS

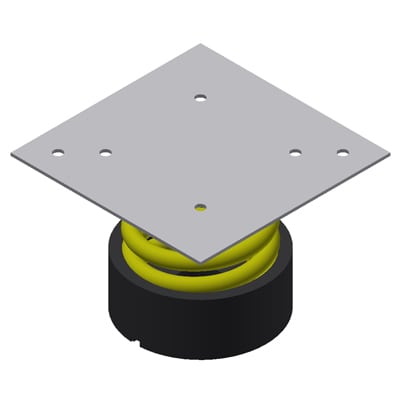

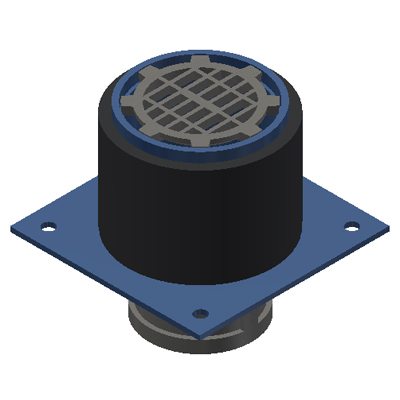

We believe that the most fool-proof and safest way to establish the air gap is the jack-up or lift-slab method. Plastic sheeting is placed on the sub-floor as a breaker layer, isolators are placed on the plastic sheeting, reinforcing steel or mesh rests on the isolator housings, and the concrete floor is poured. After the concrete has cured, the slab is lifted to elevation by turning adjustment bolts above each isolator to any specified air gap between 1” and 4”.

| TYPE | SIZE | RATED CAPACITY (VERT.) |

RATED CAPACITY (HORIZ.) |

| SFFS | 3 | 5520 lbs/ 2512 kg | 7750 lbs / 3527 kg |

| SFFS | 4 | 5520 lbs/ 2512 kg | 7750 lbs / 3527 kg |

| SFFS | 5 | 5520 lbs/ 2512 kg | 7750 lbs / 3527 kg |

| SFFS | 6 | 5520 lbs/ 2512 kg | 7750 lbs / 3527 kg |

| SFFS | 8 | 5520 lbs/ 2512 kg | 7750 lbs / 3527 kg |